What product types do wire wound inductors include?

What Product Types Do Wire Wound Inductors Include?

I. Introduction

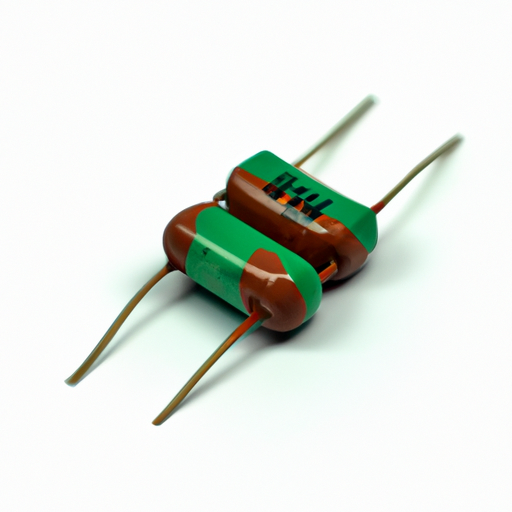

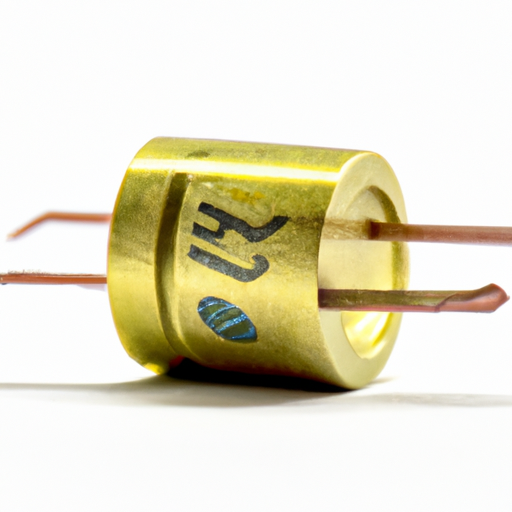

Wire wound inductors are essential components in the world of electronics, playing a crucial role in various applications ranging from power supplies to radio frequency circuits. These inductors are constructed by winding a wire around a core material, which can be air, ferrite, or iron, to create a magnetic field that stores energy. Understanding the different types of wire wound inductors and their applications is vital for engineers and designers in selecting the right components for their projects. This article will explore the various product types of wire wound inductors, their characteristics, applications, and the factors influencing their selection.

II. Basic Principles of Inductance

A. Explanation of Inductance

Inductance is the property of an electrical conductor that opposes a change in current. When current flows through a wire, it generates a magnetic field around it. If the current changes, the magnetic field also changes, inducing a voltage in the wire that opposes the change in current. This phenomenon is known as self-inductance. Inductors are designed to take advantage of this property, allowing them to store energy in the magnetic field and release it when needed.

B. Role of Wire Wound Inductors in Circuits

Wire wound inductors are widely used in electronic circuits for filtering, energy storage, and signal processing. They can smooth out voltage fluctuations, block high-frequency signals, and store energy in power supply circuits. Their ability to handle varying frequencies and currents makes them versatile components in both analog and digital applications.

C. Key Characteristics of Inductors

The key characteristics of inductors include inductance value (measured in henries), current rating (maximum current the inductor can handle), DC resistance (resistance of the wire), and frequency response (how the inductor behaves at different frequencies). These characteristics determine the inductor's performance in a given application.

III. Types of Wire Wound Inductors

Wire wound inductors come in various types, each designed for specific applications and performance requirements. Here are some of the most common types:

A. Air Core Inductors

1. Definition and Construction

Air core inductors are constructed without a magnetic core, relying solely on the air surrounding the wire to create the magnetic field. This design minimizes losses due to core saturation and eddy currents.

2. Applications and Advantages

Air core inductors are commonly used in high-frequency applications, such as RF circuits and oscillators. Their low loss characteristics make them ideal for applications where efficiency is critical. However, they tend to have lower inductance values compared to core-based inductors.

B. Ferrite Core Inductors

1. Definition and Construction

Ferrite core inductors use a ferrite material as the core, which enhances the magnetic field and increases the inductance. Ferrite cores are made from a mixture of iron oxide and other metal oxides, providing high magnetic permeability.

2. Applications and Advantages

These inductors are widely used in power supply circuits, filters, and transformers due to their ability to handle high frequencies and currents. Ferrite core inductors are compact and efficient, making them suitable for modern electronic devices.

C. Iron Core Inductors

1. Definition and Construction

Iron core inductors utilize a solid iron core to increase inductance. The iron core provides a high magnetic permeability, allowing for greater energy storage.

2. Applications and Advantages

Iron core inductors are often used in low-frequency applications, such as audio equipment and power transformers. They can handle high power levels but may suffer from core saturation at high frequencies.

D. Toroidal Inductors

1. Definition and Construction

Toroidal inductors are wound in a circular shape around a toroidal core, which can be made of ferrite or iron. This design minimizes electromagnetic interference and enhances efficiency.

2. Applications and Advantages

Toroidal inductors are commonly used in power supplies, audio equipment, and RF applications. Their compact design and low electromagnetic interference make them ideal for sensitive electronic circuits.

E. Choke Inductors

1. Definition and Construction

Choke inductors are designed to block high-frequency AC signals while allowing DC or low-frequency signals to pass. They can be constructed with various core materials, including air, ferrite, or iron.

2. Applications and Advantages

Choke inductors are widely used in power supply circuits, audio systems, and radio frequency applications. They help filter out unwanted noise and protect sensitive components from high-frequency interference.

F. SMD (Surface Mount Device) Inductors

1. Definition and Construction

SMD inductors are compact inductors designed for surface mounting on printed circuit boards (PCBs). They are available in various shapes and sizes, making them suitable for modern electronic designs.

2. Applications and Advantages

SMD inductors are commonly used in mobile devices, computers, and other compact electronic devices. Their small size and ease of integration into PCBs make them popular in contemporary electronics.

IV. Specialized Wire Wound Inductors

In addition to the standard types of wire wound inductors, there are specialized inductors designed for specific applications:

A. High-Frequency Inductors

1. Definition and Characteristics

High-frequency inductors are designed to operate efficiently at radio frequencies (RF) and above. They typically have low DC resistance and are constructed to minimize parasitic capacitance.

2. Applications in RF and Communication

These inductors are used in RF amplifiers, oscillators, and communication devices, where maintaining signal integrity is crucial.

B. Power Inductors

1. Definition and Characteristics

Power inductors are designed to handle high currents and are optimized for energy storage in power supply circuits. They often feature low DC resistance and high saturation current ratings.

2. Applications in Power Supply Circuits

Power inductors are commonly used in DC-DC converters, voltage regulators, and battery management systems, where efficient energy transfer is essential.

C. Current Sense Inductors

1. Definition and Characteristics

Current sense inductors are designed to measure current flow in a circuit. They typically have a low inductance value and are used in feedback loops for current regulation.

2. Applications in Current Measurement

These inductors are used in power management systems, motor control circuits, and battery monitoring applications, where accurate current measurement is critical.

D. Inductor Arrays

1. Definition and Construction

Inductor arrays consist of multiple inductors integrated into a single package. This design allows for compact layouts and efficient use of PCB space.

2. Applications and Advantages

Inductor arrays are commonly used in power supply circuits, filters, and RF applications, providing flexibility and reducing the overall footprint of the circuit.

V. Factors Influencing the Selection of Wire Wound Inductors

When selecting wire wound inductors for a specific application, several factors must be considered:

A. Inductance Value

The inductance value must match the requirements of the circuit, as it determines the inductor's ability to store energy and filter signals.

B. Current Rating

The inductor's current rating should exceed the maximum current expected in the application to prevent overheating and damage.

C. DC Resistance

Low DC resistance is essential for minimizing power losses and improving efficiency, especially in power applications.

D. Frequency Response

The inductor's performance at different frequencies should be evaluated to ensure it meets the application's requirements.

E. Size and Form Factor

The physical size and form factor of the inductor should be compatible with the design constraints of the circuit.

F. Environmental Considerations

Factors such as temperature, humidity, and exposure to chemicals should be considered, as they can affect the inductor's performance and longevity.

VI. Manufacturing and Quality Control

A. Overview of Manufacturing Processes

Wire wound inductors are manufactured through various processes, including winding, core assembly, and encapsulation. Advanced techniques ensure precision and consistency in production.

B. Quality Control Measures

Quality control measures, such as testing inductance values, current ratings, and resistance, are implemented to ensure that inductors meet industry standards and specifications.

C. Standards and Certifications

Manufacturers often adhere to international standards and certifications, such as ISO and RoHS, to ensure product quality and environmental compliance.

VII. Future Trends in Wire Wound Inductors

A. Innovations in Materials and Design

Advancements in materials, such as high-temperature superconductors and nanocrystalline cores, are expected to enhance the performance of wire wound inductors.

B. Impact of Emerging Technologies

The rise of electric vehicles, renewable energy systems, and IoT devices is driving demand for more efficient and compact inductors, leading to innovations in design and manufacturing.

C. Market Trends and Predictions

The market for wire wound inductors is expected to grow, driven by increasing demand for electronic devices and advancements in technology. Manufacturers will need to adapt to changing requirements and invest in research and development.

VIII. Conclusion

Wire wound inductors are vital components in modern electronics, with various types designed for specific applications. Understanding the different product types, their characteristics, and the factors influencing their selection is essential for engineers and designers. As technology continues to evolve, wire wound inductors will play an increasingly important role in shaping the future of electronic devices.

IX. References

A. Academic Journals

- IEEE Transactions on Power Electronics

- Journal of Applied Physics

B. Industry Publications

- Electronic Design Magazine

- Power Electronics Technology

C. Manufacturer Specifications and Data Sheets

- Coilcraft

- Vishay Intertechnology

This comprehensive overview of wire wound inductors highlights their significance in electronic applications and provides valuable insights for selecting the right components for various projects.