What is the capacitor structure like?

What is the Capacitor Structure Like?

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and timing applications. Defined as passive electrical devices that store energy in an electric field, capacitors are essential for the proper functioning of various electronic systems. Understanding the structure of capacitors is vital for engineers and hobbyists alike, as it influences their performance and suitability for specific applications. This blog post will delve into the intricate structure of capacitors, exploring their components, types, manufacturing processes, and applications.

II. Basic Principles of Capacitance

A. Definition of Capacitance

Capacitance is the ability of a capacitor to store an electric charge. It is defined as the ratio of the electric charge (Q) stored on the conductive plates to the voltage (V) across them, expressed mathematically as:

\[ C = \frac{Q}{V} \]

Where \( C \) is the capacitance measured in farads (F), \( Q \) is the charge in coulombs (C), and \( V \) is the voltage in volts (V).

B. Role of Electric Fields in Capacitance

When a voltage is applied across the conductive plates of a capacitor, an electric field is established between them. This electric field is responsible for storing energy in the capacitor. The strength of the electric field is directly proportional to the voltage and inversely proportional to the distance between the plates.

C. Factors Affecting Capacitance

Several factors influence the capacitance of a capacitor:

1. **Area of the Plates**: The larger the surface area of the conductive plates, the greater the capacitance, as more charge can be stored.

2. **Distance Between Plates**: The closer the plates are to each other, the higher the capacitance, as the electric field strength increases.

3. **Dielectric Material**: The type of dielectric material used between the plates significantly affects capacitance. Different materials have varying dielectric constants, which enhance or reduce the capacitor's ability to store charge.

III. Components of a Capacitor

A. Conductive Plates

1. Description and Function

The conductive plates are the primary components of a capacitor, responsible for storing electric charge. When a voltage is applied, one plate accumulates positive charge while the other accumulates negative charge, creating an electric field between them.

2. Materials Used

Common materials for conductive plates include aluminum, tantalum, and copper. Aluminum is widely used due to its excellent conductivity and cost-effectiveness, while tantalum is favored for its high capacitance in a small volume.

B. Dielectric Material

1. Definition and Purpose

The dielectric material is an insulating substance placed between the conductive plates. Its primary purpose is to increase the capacitor's capacitance by allowing the electric field to develop without allowing current to flow between the plates.

2. Types of Dielectric Materials

There are several types of dielectric materials, including:

Ceramic: Commonly used in small capacitors, ceramic dielectrics offer stability and reliability.

Electrolytic: These capacitors use a liquid electrolyte as the dielectric, providing high capacitance values in a compact size.

Film: Made from plastic films, these capacitors are known for their stability and low loss.

3. Impact of Dielectric Properties on Performance

The dielectric constant of the material directly affects the capacitor's performance. A higher dielectric constant allows for greater charge storage, while the dielectric's breakdown voltage determines the maximum voltage the capacitor can handle before failing.

C. Terminals

1. Function and Connection to Circuits

Terminals are the conductive leads that connect the capacitor to an electronic circuit. They allow the stored charge to be accessed and utilized in various applications.

2. Types of Terminals

Capacitors come with different terminal types, including:

Leaded: These capacitors have long leads for through-hole mounting on circuit boards.

Surface Mount: These capacitors are designed for surface mounting, allowing for compact designs and automated assembly.

IV. Types of Capacitor Structures

A. Parallel Plate Capacitor

1. Structure and Working Principle

The parallel plate capacitor consists of two flat conductive plates separated by a dielectric material. When a voltage is applied, an electric field is established between the plates, allowing for charge storage.

2. Applications and Limitations

Parallel plate capacitors are commonly used in various applications, including timing circuits and filters. However, their size and limited capacitance range can be a drawback in some scenarios.

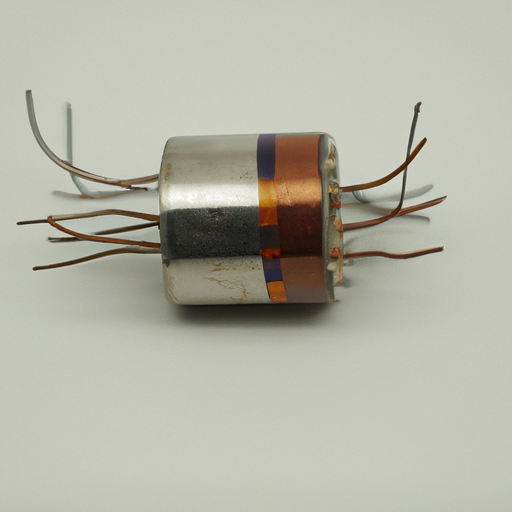

B. Cylindrical Capacitor

1. Structure and Working Principle

Cylindrical capacitors consist of two concentric cylindrical conductive plates with a dielectric material in between. The electric field is established radially, allowing for efficient charge storage.

2. Applications and Limitations

These capacitors are often used in high-voltage applications due to their ability to handle larger electric fields. However, their manufacturing complexity can lead to higher costs.

C. Spherical Capacitor

1. Structure and Working Principle

Spherical capacitors consist of two concentric spherical conductive shells separated by a dielectric. The electric field is uniform throughout the space between the shells, providing consistent performance.

2. Applications and Limitations

Spherical capacitors are used in specialized applications, such as in certain types of sensors. Their unique structure can make them less common in general electronics.

D. Specialized Capacitor Structures

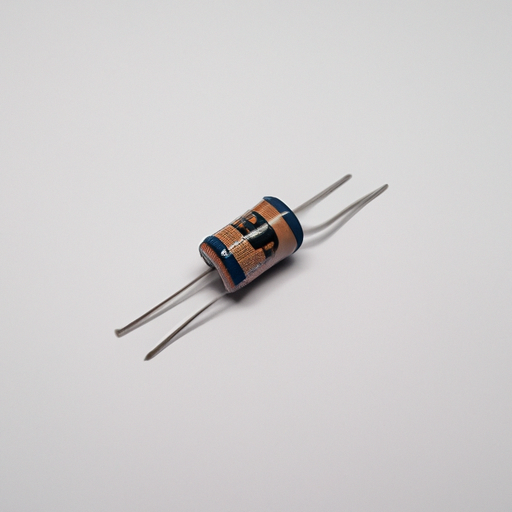

1. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance and reliability in compact sizes. They are often used in applications requiring stable performance, such as in mobile devices.

2. Ceramic Capacitors

Ceramic capacitors are widely used due to their stability and low cost. They are available in various capacitance values and are commonly found in consumer electronics.

3. Supercapacitors

Supercapacitors, or ultracapacitors, are designed for high energy storage and rapid charge/discharge cycles. They are used in applications requiring quick bursts of energy, such as in regenerative braking systems.

V. Manufacturing Processes

A. Overview of Capacitor Manufacturing

The manufacturing of capacitors involves several steps, from material selection to assembly and testing. Each step is crucial to ensure the final product meets performance and reliability standards.

B. Steps in the Production of Capacitors

1. Material Selection

Choosing the right materials for conductive plates and dielectrics is essential for achieving desired capacitance and performance characteristics.

2. Layering and Assembly

The layering process involves stacking the conductive plates and dielectric material in a precise manner. This can be done through various methods, including winding, stacking, or layering.

3. Testing and Quality Control

Once assembled, capacitors undergo rigorous testing to ensure they meet specifications. This includes checking capacitance values, leakage current, and breakdown voltage.

VI. Applications of Capacitors

A. Role in Energy Storage

Capacitors are widely used for energy storage in various applications, from power supply smoothing to energy recovery systems in electric vehicles.

B. Use in Filtering and Smoothing Circuits

In electronic circuits, capacitors help filter out noise and smooth voltage fluctuations, ensuring stable operation.

C. Applications in Timing and Oscillation Circuits

Capacitors are essential in timing circuits, where they work with resistors to create time delays. They are also used in oscillators to generate specific frequencies.

D. Capacitors in Power Electronics

In power electronics, capacitors play a vital role in managing power flow, improving efficiency, and stabilizing voltage levels.

VII. Conclusion

Understanding the structure and function of capacitors is essential for anyone involved in electronics. From their basic principles of capacitance to the various types and manufacturing processes, capacitors are integral to modern technology. As electronic devices continue to evolve, so too will capacitor technology, with advancements in materials and designs paving the way for more efficient and compact solutions.

VIII. References

For further reading on capacitor technology and design, consider exploring the following resources:

- "Capacitors: Technology and Applications" by John Smith

- "Fundamentals of Electric Circuits" by Charles Alexander and Matthew Sadiku

- Academic journals and articles on capacitor research and development.

By understanding the intricacies of capacitor structures, engineers and enthusiasts can make informed decisions about their use in electronic circuits, ultimately leading to better designs and innovations in technology.