What product types are included in aluminum capacitors?

What Product Types are Included in Aluminum Capacitors?

I. Introduction

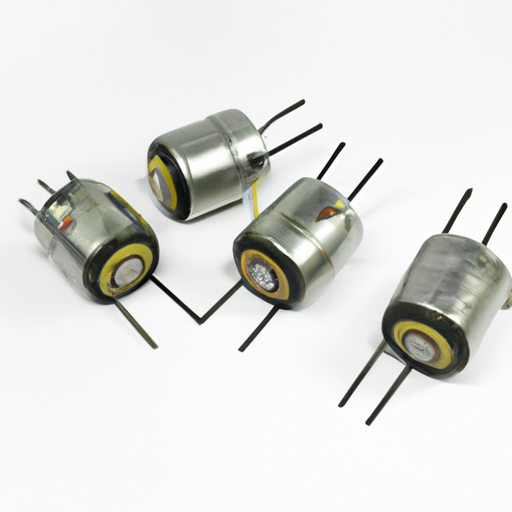

Aluminum capacitors are essential components in the world of electronics, playing a crucial role in various applications ranging from consumer electronics to industrial machinery. These capacitors are known for their ability to store and release electrical energy, making them vital for smoothing out voltage fluctuations, filtering signals, and providing power in electronic circuits. In this article, we will explore the different types of aluminum capacitors, their structures, functions, and applications, as well as future trends in this technology.

II. Basic Structure and Function of Aluminum Capacitors

A. Components of Aluminum Capacitors

Aluminum capacitors consist of three primary components:

1. **Anode**: The anode is typically made of aluminum foil, which is oxidized to form a thin layer of aluminum oxide. This oxide layer acts as the dielectric material, allowing the capacitor to store electrical energy.

2. **Cathode**: The cathode is usually a liquid electrolyte that surrounds the anode. This electrolyte facilitates the flow of electric current and completes the circuit.

3. **Dielectric**: The dielectric in aluminum capacitors is the aluminum oxide layer formed on the anode. This layer is crucial for the capacitor's ability to store charge.

B. Working Principle

The working principle of aluminum capacitors is based on the ability of the dielectric material to separate charges. When a voltage is applied across the capacitor, positive charges accumulate on the anode, while negative charges gather on the cathode. This separation of charges creates an electric field, allowing the capacitor to store energy. When the voltage is removed, the stored energy can be released back into the circuit.

C. Advantages of Aluminum Capacitors

Aluminum capacitors offer several advantages, including:

High Capacitance Values: They can achieve high capacitance values in a relatively small size, making them suitable for various applications.

Cost-Effectiveness: Compared to other types of capacitors, aluminum capacitors are generally more affordable.

Wide Availability: They are widely available in different specifications, making them easy to source for various projects.

III. Types of Aluminum Capacitors

Aluminum capacitors come in several types, each designed for specific applications and performance requirements.

A. Aluminum Electrolytic Capacitors

1. **Description and Characteristics**: Aluminum electrolytic capacitors are the most common type. They feature a high capacitance value and are polarized, meaning they have a positive and negative terminal.

2. **Applications**: These capacitors are widely used in power supply circuits, audio equipment, and various consumer electronics due to their ability to handle high ripple currents.

B. Aluminum Polymer Capacitors

1. **Description and Characteristics**: Aluminum polymer capacitors use a conductive polymer as the electrolyte instead of a liquid. This design results in lower equivalent series resistance (ESR) and improved performance at high frequencies.

2. **Applications**: They are commonly used in high-performance applications such as computer motherboards, graphics cards, and audio equipment.

C. Aluminum Foil Capacitors

1. **Description and Characteristics**: These capacitors utilize aluminum foil as both the anode and cathode. They are known for their high reliability and stability.

2. **Applications**: Aluminum foil capacitors are often used in applications requiring high voltage and capacitance stability, such as power electronics and industrial equipment.

D. SMD (Surface Mount Device) Aluminum Capacitors

1. **Description and Characteristics**: SMD aluminum capacitors are designed for surface mounting on printed circuit boards (PCBs). They are compact and suitable for automated assembly processes.

2. **Applications**: These capacitors are commonly found in smartphones, tablets, and other compact electronic devices.

E. High-Temperature Aluminum Capacitors

1. **Description and Characteristics**: High-temperature aluminum capacitors are designed to operate in extreme temperature conditions, often exceeding 105°C.

2. **Applications**: They are used in automotive applications, industrial machinery, and other environments where high temperatures are prevalent.

F. Low-ESR (Equivalent Series Resistance) Aluminum Capacitors

1. **Description and Characteristics**: Low-ESR aluminum capacitors are engineered to minimize energy loss during operation, making them ideal for high-frequency applications.

2. **Applications**: These capacitors are commonly used in power supply circuits, audio amplifiers, and other applications where efficiency is critical.

IV. Specialized Aluminum Capacitors

In addition to the standard types, there are specialized aluminum capacitors designed for specific applications.

A. Audio Capacitors

1. **Description and Characteristics**: Audio capacitors are designed to enhance sound quality by minimizing distortion and improving frequency response.

2. **Applications in Audio Equipment**: They are commonly used in high-fidelity audio systems, amplifiers, and other audio equipment to ensure optimal performance.

B. Power Supply Capacitors

1. **Description and Characteristics**: Power supply capacitors are designed to handle high voltage and current levels, providing stability and filtering in power supply circuits.

2. **Applications in Power Supply Circuits**: These capacitors are essential in switching power supplies, voltage regulators, and other power management systems.

C. Motor Run Capacitors

1. **Description and Characteristics**: Motor run capacitors are used in electric motors to improve efficiency and performance.

2. **Applications in Electric Motors**: They are commonly found in HVAC systems, pumps, and other applications where electric motors are used.

V. Comparison of Aluminum Capacitor Types

A. Performance Metrics

1. **Capacitance Range**: Different types of aluminum capacitors offer varying capacitance ranges, with electrolytic capacitors typically providing the highest values.

2. **Voltage Ratings**: Voltage ratings vary among capacitor types, with specialized capacitors designed for high-voltage applications.

3. **ESR and Ripple Current**: Low-ESR capacitors are preferred in high-frequency applications, while standard electrolytic capacitors may have higher ESR values.

B. Cost Considerations

Cost can vary significantly among different types of aluminum capacitors. While standard electrolytic capacitors are generally the most affordable, specialized capacitors may come at a premium due to their enhanced performance characteristics.

C. Lifespan and Reliability

The lifespan and reliability of aluminum capacitors can differ based on their design and application. High-temperature and low-ESR capacitors tend to have longer lifespans, making them suitable for demanding environments.

VI. Future Trends in Aluminum Capacitor Technology

A. Innovations in Materials and Design

The aluminum capacitor industry is witnessing innovations in materials and design, leading to improved performance and efficiency. New dielectric materials and manufacturing techniques are being explored to enhance capacitance and reduce ESR.

B. Environmental Considerations

As environmental concerns grow, manufacturers are focusing on developing eco-friendly aluminum capacitors. This includes using recyclable materials and reducing the environmental impact of production processes.

C. Market Demand and Growth Projections

The demand for aluminum capacitors is expected to grow, driven by advancements in technology and the increasing use of electronics in various industries. This growth presents opportunities for manufacturers to innovate and expand their product offerings.

VII. Conclusion

In summary, aluminum capacitors are vital components in modern electronics, offering a wide range of types and applications. From standard electrolytic capacitors to specialized variants, each type serves a unique purpose in electronic circuits. As technology continues to evolve, so too will the design and functionality of aluminum capacitors, ensuring their relevance in the ever-changing landscape of electronics. When selecting an aluminum capacitor, it is essential to consider factors such as capacitance, voltage rating, and application requirements to ensure optimal performance.

VIII. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications and Guidelines

This comprehensive overview of aluminum capacitors highlights their importance, diversity, and future potential in the electronics industry. Understanding the various types and their applications can help engineers and designers make informed decisions when selecting capacitors for their projects.