What are the popular overload capacitor product models?

Popular Overload Capacitor Product Models

I. Introduction

A. Definition of Overload Capacitors

Overload capacitors are essential components in electrical systems, designed to manage excess voltage and current. They play a critical role in stabilizing electrical circuits, ensuring that devices operate efficiently and safely. By temporarily storing electrical energy, these capacitors can help prevent damage to sensitive equipment during overload conditions.

B. Importance of Overload Capacitors in Electrical Systems

In modern electrical systems, the reliability and longevity of equipment are paramount. Overload capacitors help mitigate the risks associated with voltage spikes and surges, which can lead to equipment failure or even catastrophic incidents. Their ability to absorb excess energy makes them indispensable in various applications, from industrial machinery to consumer electronics.

C. Purpose of the Article

This article aims to provide an overview of popular overload capacitor product models, highlighting their specifications, applications, and advantages. By understanding the available options, readers can make informed decisions when selecting overload capacitors for their specific needs.

II. Understanding Overload Capacitors

A. What are Overload Capacitors?

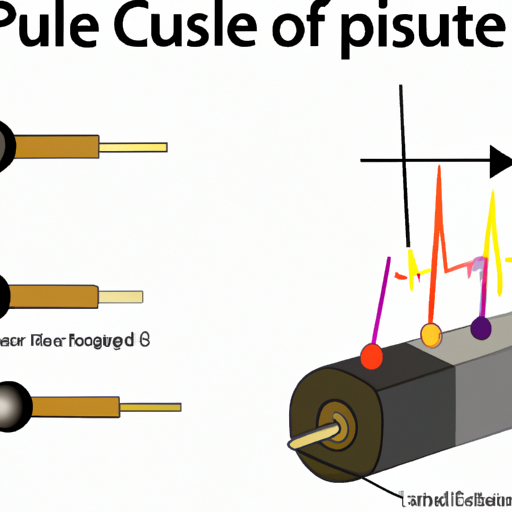

1. Function and Role in Electrical Circuits

Overload capacitors serve as temporary energy storage devices that can absorb excess voltage and current during transient conditions. They help maintain voltage stability, reduce electrical noise, and improve the overall performance of electrical systems. By doing so, they protect sensitive components from damage and enhance the reliability of the entire system.

2. Types of Overload Capacitors

There are several types of overload capacitors, including:

Electrolytic Capacitors: Known for their high capacitance values, these capacitors are commonly used in power supply circuits.

Film Capacitors: These capacitors offer excellent stability and low losses, making them suitable for high-frequency applications.

Ceramic Capacitors: With their small size and high reliability, ceramic capacitors are often used in consumer electronics.

B. Key Specifications and Ratings

When selecting overload capacitors, it is crucial to consider their specifications and ratings:

1. Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle without failure. It is essential to choose a capacitor with a voltage rating higher than the maximum operating voltage of the circuit.

2. Capacitance Value

The capacitance value, measured in microfarads (µF), determines the amount of electrical energy the capacitor can store. Selecting the appropriate capacitance value is vital for ensuring optimal performance in the intended application.

3. Temperature Rating

Capacitors are rated for specific temperature ranges. Operating outside these limits can lead to reduced performance or failure. It is essential to consider the environmental conditions in which the capacitor will be used.

4. Tolerance Levels

Tolerance levels indicate the permissible variation in capacitance value. A lower tolerance level means higher precision, which is crucial for applications requiring exact capacitance values.

III. Popular Overload Capacitor Product Models

A. Overview of Leading Manufacturers

Several manufacturers are recognized for producing high-quality overload capacitors. These companies have established a reputation for reliability and performance in the industry.

1. Company Profiles

Panasonic: Known for its innovative technology and wide range of capacitors, Panasonic is a leading manufacturer in the electronics industry.

Vishay: With a strong focus on quality and performance, Vishay offers a variety of capacitors suitable for various applications.

KEMET: KEMET is renowned for its advanced capacitor technologies, providing solutions for demanding applications.

B. Detailed Review of Popular Models

1. Model A: Panasonic ECW-FD Series

Specifications: Voltage rating of 250V, capacitance values ranging from 0.1µF to 10µF, temperature rating of -40°C to +105°C.

Applications: Suitable for power supply circuits, audio equipment, and industrial machinery.

Advantages and Disadvantages: Offers excellent stability and low losses; however, it may be more expensive than other options.

2. Model B: Vishay 1812 Series

Specifications: Voltage rating of 50V to 100V, capacitance values from 1µF to 100µF, temperature rating of -55°C to +125°C.

Applications: Ideal for automotive, telecommunications, and consumer electronics.

Advantages and Disadvantages: High reliability and performance; however, it may have a larger footprint compared to other models.

3. Model C: KEMET C4AE Series

Specifications: Voltage rating of 250V, capacitance values from 0.1µF to 22µF, temperature rating of -55°C to +125°C.

Applications: Used in power electronics, renewable energy systems, and industrial applications.

Advantages and Disadvantages: Excellent temperature stability; however, it may have limited availability in certain regions.

4. Model D: Nichicon UHE Series

Specifications: Voltage rating of 16V to 450V, capacitance values from 1µF to 1000µF, temperature rating of -40°C to +105°C.

Applications: Commonly used in power supply circuits and audio equipment.

Advantages and Disadvantages: High capacitance values and reliability; however, it may have a shorter lifespan under high-stress conditions.

5. Model E: Rubycon ZLJ Series

Specifications: Voltage rating of 6.3V to 450V, capacitance values from 1µF to 1000µF, temperature rating of -40°C to +105°C.

Applications: Suitable for consumer electronics, power supplies, and industrial applications.

Advantages and Disadvantages: Good performance and cost-effectiveness; however, it may not be suitable for high-frequency applications.

IV. Factors to Consider When Choosing Overload Capacitors

A. Application Requirements

Understanding the specific requirements of the application is crucial. Different applications may demand varying capacitance values, voltage ratings, and temperature tolerances.

B. Environmental Conditions

Consider the environmental conditions in which the capacitor will operate. Factors such as temperature, humidity, and exposure to chemicals can significantly impact the performance and lifespan of the capacitor.

C. Cost vs. Performance

While it may be tempting to choose the least expensive option, it is essential to balance cost with performance. Investing in a high-quality capacitor can lead to long-term savings by reducing the risk of equipment failure.

D. Manufacturer Support and Warranty

Choosing a reputable manufacturer with strong customer support and warranty options can provide peace of mind. A good warranty can protect against defects and ensure that you receive a reliable product.

V. Trends in Overload Capacitor Technology

A. Innovations in Design and Materials

Recent advancements in capacitor technology have led to the development of more efficient and compact designs. New materials, such as organic dielectrics, are being explored to enhance performance and reduce environmental impact.

B. Impact of Smart Technology on Capacitor Use

The rise of smart technology has increased the demand for capacitors that can handle higher frequencies and provide better energy efficiency. Capacitors are now being integrated into smart devices to improve performance and reliability.

C. Future Directions in Overload Capacitor Development

As technology continues to evolve, the future of overload capacitors looks promising. Ongoing research aims to develop capacitors with higher energy densities, improved thermal stability, and enhanced performance in extreme conditions.

VI. Conclusion

A. Summary of Key Points

Overload capacitors are vital components in electrical systems, providing protection against voltage spikes and ensuring reliable operation. Understanding the specifications, popular models, and selection criteria is essential for making informed decisions.

B. Final Thoughts on Selecting Overload Capacitors

When choosing overload capacitors, consider the specific requirements of your application, environmental conditions, and the balance between cost and performance. Investing in high-quality capacitors can lead to improved reliability and longevity of your electrical systems.

C. Encouragement for Further Research and Consideration

As technology continues to advance, staying informed about the latest trends and innovations in overload capacitors will help you make the best choices for your needs. Further research and exploration of available options can lead to better performance and efficiency in your electrical systems.

VII. References

A. List of Sources and Further Reading

1. Panasonic Capacitor Product Catalog

2. Vishay Capacitor Technical Data Sheets

3. KEMET Capacitor Application Notes

4. Nichicon Product Information

5. Rubycon Capacitor Specifications

B. Industry Standards and Guidelines

1. IEC 60384 - Fixed Capacitors for Use in Electronic Equipment

2. IEEE 18 - Standard for the Measurement of Capacitor Losses

3. ANSI C37.90 - Standard for Relays and Relay Systems for Power Apparatus

By understanding the importance of overload capacitors and the various models available, you can ensure that your electrical systems operate safely and efficiently.