An article to help you understand what a porcelain tube resistor is

Understanding Porcelain Tube Resistors

I. Introduction

In the world of electrical engineering, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, porcelain tube resistors stand out due to their unique properties and applications. This article aims to provide a comprehensive understanding of porcelain tube resistors, exploring their history, structure, functionality, advantages, disadvantages, and future prospects.

II. Historical Background

The development of resistors has been a significant milestone in electrical engineering. Early resistors were made from simple materials like carbon, but as technology advanced, the need for more durable and efficient components became apparent. The introduction of porcelain as a material for resistors marked a turning point in resistor technology. Porcelain, known for its high-temperature resistance and electrical insulation properties, began to be used in the mid-20th century, leading to the evolution of porcelain tube resistors. Over time, these resistors have been refined to meet the demands of modern electronics, becoming a staple in various applications.

III. What is a Porcelain Tube Resistor?

A. Description of the Structure and Materials

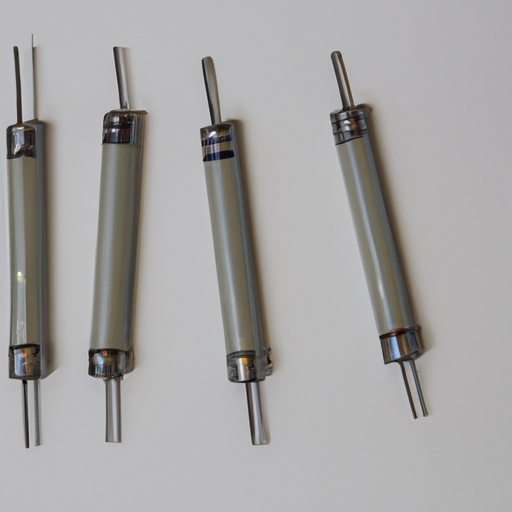

A porcelain tube resistor is characterized by its cylindrical shape, typically made from a high-quality porcelain material. Porcelain is a ceramic material composed of kaolin, feldspar, and quartz, which, when fired at high temperatures, forms a dense and durable structure. The design features of tube resistors include a central conductive element, often made of carbon or metal, encased within the porcelain tube. This design not only provides electrical resistance but also protects the conductive element from environmental factors.

B. How Porcelain Tube Resistors Differ from Other Types of Resistors

Porcelain tube resistors differ from other types of resistors, such as carbon, metal film, and wire-wound resistors, in several ways. Carbon resistors are typically less expensive but may not withstand high temperatures as effectively as porcelain tube resistors. Metal film resistors offer precision but can be more sensitive to environmental conditions. Wire-wound resistors, while durable, can be bulkier and less versatile. Porcelain tube resistors combine the benefits of durability, high-temperature resistance, and electrical insulation, making them suitable for demanding applications.

C. Common Applications of Porcelain Tube Resistors

Porcelain tube resistors are commonly used in high-voltage applications, such as power supplies, industrial machinery, and telecommunications equipment. Their ability to withstand extreme temperatures and environmental conditions makes them ideal for outdoor installations and harsh environments. Additionally, they are often found in audio equipment, where their stability and reliability are essential for optimal performance.

IV. Working Principle

A. Basic Principles of Resistance and Electrical Flow

At its core, resistance is a measure of how much a material opposes the flow of electric current. The basic principle of resistance is governed by Ohm's Law, which states that the current flowing through a conductor between two points is directly proportional to the voltage across the two points and inversely proportional to the resistance. In the case of porcelain tube resistors, the conductive element within the porcelain tube provides the necessary resistance to control the flow of current.

B. How Porcelain Tube Resistors Function in a Circuit

When a porcelain tube resistor is placed in an electrical circuit, it limits the amount of current that can flow through it. The resistance value of the resistor determines how much current will pass for a given voltage. As current flows through the resistor, it generates heat due to the resistance, which is dissipated into the surrounding environment. The porcelain casing helps to manage this heat, ensuring that the resistor operates within safe temperature limits.

C. Factors Affecting Resistance in Porcelain Tube Resistors

Several factors can affect the resistance of porcelain tube resistors, including temperature, humidity, and the quality of the materials used. As temperature increases, the resistance of the conductive element may change, impacting the overall performance of the resistor. Additionally, exposure to moisture or chemicals can degrade the porcelain material, potentially leading to failure.

V. Advantages of Porcelain Tube Resistors

A. High-Temperature Resistance

One of the primary advantages of porcelain tube resistors is their ability to withstand high temperatures. This makes them suitable for applications where heat dissipation is a concern, such as in power electronics and industrial machinery.

B. Durability and Longevity

Porcelain is a robust material that offers excellent durability and longevity. Porcelain tube resistors can operate effectively over extended periods, reducing the need for frequent replacements and maintenance.

C. Electrical Insulation Properties

The electrical insulation properties of porcelain help prevent short circuits and other electrical failures. This is particularly important in high-voltage applications, where insulation is critical for safety and performance.

D. Resistance to Environmental Factors

Porcelain tube resistors are resistant to moisture, chemicals, and other environmental factors that can affect performance. This makes them ideal for outdoor applications and in industries where exposure to harsh conditions is common.

VI. Disadvantages of Porcelain Tube Resistors

A. Cost Considerations

While porcelain tube resistors offer many advantages, they can be more expensive than other types of resistors. The cost of materials and manufacturing processes can contribute to a higher price point, which may be a consideration for budget-conscious projects.

B. Size and Weight Limitations

Porcelain tube resistors tend to be larger and heavier than other resistor types, which can limit their use in compact electronic devices. Designers must consider the physical dimensions of these resistors when integrating them into circuits.

C. Potential for Brittleness and Breakage

Despite their durability, porcelain tube resistors can be brittle and susceptible to breakage if subjected to mechanical stress or impact. Care must be taken during installation and handling to prevent damage.

VII. Installation and Usage

A. Guidelines for Installing Porcelain Tube Resistors

When installing porcelain tube resistors, it is essential to follow manufacturer guidelines to ensure proper functionality. This includes ensuring that the resistor is mounted securely and that there is adequate space for heat dissipation.

B. Best Practices for Usage in Various Applications

To maximize the performance of porcelain tube resistors, it is important to select the appropriate resistance value for the specific application. Additionally, monitoring temperature and environmental conditions can help prevent issues related to overheating or degradation.

C. Safety Considerations When Working with Resistors

Safety is paramount when working with electrical components. Always ensure that power is disconnected before handling resistors, and use appropriate personal protective equipment (PPE) to prevent injury.

VIII. Maintenance and Troubleshooting

A. Routine Checks and Maintenance Tips

Regular maintenance of porcelain tube resistors can help identify potential issues before they become critical. Routine checks should include inspecting for signs of wear, damage, or discoloration.

B. Common Issues and How to Address Them

Common issues with porcelain tube resistors may include overheating, changes in resistance value, or physical damage. If a resistor is suspected to be malfunctioning, it should be tested with a multimeter, and if necessary, replaced.

C. When to Replace a Porcelain Tube Resistor

If a porcelain tube resistor shows signs of significant wear, damage, or failure to perform as expected, it should be replaced promptly to prevent further issues in the circuit.

IX. Future of Porcelain Tube Resistors

A. Innovations in Resistor Technology

As technology continues to advance, innovations in resistor technology are likely to emerge. This may include the development of new materials that enhance performance and reduce costs.

B. Potential Developments in Materials and Design

Future developments may focus on improving the properties of porcelain or exploring alternative materials that offer similar benefits with reduced weight and size.

C. The Role of Porcelain Tube Resistors in Modern Electronics

Despite the emergence of new technologies, porcelain tube resistors will likely continue to play a vital role in modern electronics, particularly in applications requiring high reliability and durability.

X. Conclusion

In summary, porcelain tube resistors are an essential component in the field of electrical engineering, offering unique advantages in terms of durability, high-temperature resistance, and electrical insulation. Understanding their structure, functionality, and applications is crucial for anyone working with electronic circuits. As technology evolves, the role of porcelain tube resistors will continue to be significant, making it worthwhile for engineers and enthusiasts alike to explore this fascinating topic further.

XI. References

For those interested in delving deeper into the subject of porcelain tube resistors and resistor technology, the following resources are recommended:

1. "Resistor Technology: A Comprehensive Guide" - An in-depth look at various resistor types and their applications.

2. "Materials Science in Electronics" - A collection of academic papers discussing advancements in materials used in electronic components.

3. "The Evolution of Electrical Engineering" - A historical overview of key developments in the field, including resistors.

By understanding porcelain tube resistors, we can appreciate their significance in the ever-evolving landscape of electronics and electrical engineering.